Our Products / Services

ROLLING MILL STANDS

Mill Stands are Machined on world class Machinery with regular quality checks from Casting, Machining till Assembly. Mill Stands range from 6 inch size up to 30 inch size . Here, we make use of only Steel Casting C.I Ultra sonically tested material in grades as per the specified requirements so as to provide for optimum functional support in the offered Mill Stand range. Our expertise lies in providing these in Roller Bearing and Fiber Bearing Mill Stands depending on the requirement of the Mill

GEAR BOX

We are engaged in offering quality certified range of Industrial Gear Box that is widely demanded in Rolling Mills, Sugar Mills, Cold Rolling Mill Plants, Steel Industry and Automotive Industry. Our Gear Boxes are tested on the international parameters under the supervision of experienced professions.

TYPES

Spur Gearbox

Helical Gearbox

Planetary Gearbox

Bevel Gearbox

TMT QUENCHING BOX

We providing high quality TMT quenching system. These products are available as per specific requirements of our clients. These can be availed at very competitive rates.

Range 18m length & 32 m/s of TMT box.

RACK TYPE AUTOMATIC COOLING BED

COOLING BED ENSURES PROPER COOLING OF BARS WITH REQUIRED STRAIGHTNESS FOR CAPACITY UPTO 60T/HR. RACK TYPE AUTOMATIC COOLING BED TRANSFER THE MATERIAL BY ONE PITCH FOR EVERY RACK MOVEMENT. THERE ARE PROVIDED WITH TWIN CHANNEL BAR DELIVERY SYSTEM.

TURN OVER COOLING BED FOR ALLOY STEEL ROTATES THE BARS BY ONE REVOLUTIONS EVERY TIME THE RAKES MOVE BY A PITCH.

COLD SHEAR MACHINE

COLD BAR SHEAR MACHINE OFFERED IS MADE AVAILABLE BY US IN PRECISION DESIGNED & CONSTRUCTED FINISH SO AS TO PROVIDE DESIRABLE SUPPORT TO THE PROCESS OF CUTTING BUNDLE OF BARS ON COOLING BED.

KEY POINTS :-

- UPTO 25 TONS

- UPTO 800 MM BLADE LENGTH.

- 150 MM STROKE (HYD / MECH)

- CAPACITY:

TO CUT 120 PCS. OF 8MM, 80 PC OF 10MM, 60 PCS OF 12MM, 35PCS OF 16MM, 18 PCS. OF 20MM, 14 PCS. OF 25MM, 8 PCS. OF 32MM COLD BARS, 4 PCS. OF 36MM COLD T.M.T. BARS & 2 PCS. OF 40MM.

FLYING SHEAR

PRIMARILY USED IN HOT ROLLING MILL. IT IS KNOWN FOR CUTTING THE HEAVY METAL BARS. OUR FLYING SHEARING MACHINE IS USED TO CUT THE MATERIAL OF VARIOUS SIZES, IN DIFFERENT LENGTHS OF SHEARING MACHINES WITH FLYING ARM EFFECTS. BAR CUTTING CAPACITY FROM 12M/S UP TO 20M/S. IT IS INSTALLED AFTER THE SHEARING MACHINES AND BEFORE THE COOLING BED.

KEY NOTES :

- AVAILABLE UPTO 1200 MM CRS.

- TMT BAR TEMPRATURE ARROUND 500 – 600 DEGREES

WITH SPEED OF MORE THAN 500 RPM

BILLET SHEARING MACHINE

BILLET SHEARING MACHINES ARE FABRICATED FROM TESTED ROLLED PLATES FROM MAIN PRODUCERS. ALL THE DRIVE GEARS ARE MANUFACTURED OUT OF FORGED EN9/19/24 STEEL WHICH DULY HARDEND & GROUNDED. THE SHAFT IS FORGED EN8/9 STEEL. ALL BEARING ARE OF BEST QUALITY ETC. GUN METAL BUSHES ARE MADE WITH COPPER ALLOY TO LIFE LONG.

KEY POINTS :

- CAPACITY UPTO 8” BILLETS, 12” X 3” SLABS

- PRODUCTION UPTO 300 TONS /DAY

- MOTOR REQUIRED UPTO 100 H.P.

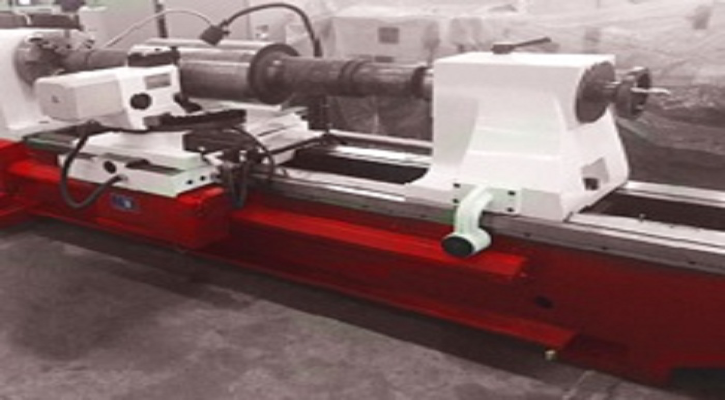

CNC ROLL NOTCHING & BRANDING MACHINE

: FEATURES

- TYPICAL TRADITIONAL DESIGN T O GET SWIVEL FUNCTION AND FLY CUTTING FUNCTION IN ONE UNIT.

- SUITABLE FOR CASTING ROLLS AND TUNGSTEN CARBIDE ROLL RINGS.

- STURDY AND RIGID MACHINE CONSTRUCTION.

- ONE M A C H I N E F O R T W O J O B S : ROLL NOTCHING & NAME MARKING. ONE STATION TO GET ALL JOB DONE.

- FULLY AUTOMATIC NOTCHING FROM FIRST GROVE TO LAST GROOVE AT SAME SIZE.

- EQUIPPED WITH ‘SIEMENS’ HIGH PERFORMANCE 4-AXIS CNC SYSTEM. USER FRIENDLY & EASY TO OPERATE.

- CNC SYSTEM CAN CONTINUE CUTTING JOB FROM PAUSE POSITION AFTER TOOL CHANGED DURING CUTTING PROCESS.

- HIGH PRECISION BALL SCREW TO ENSURE PRECISION TRANSMISSION FOR LONGITUDINAL.

- PRECISION ROLLING ARC GUIDE-WAY PROVIDE SWIVEL HEAD WITH FINE POSITION SUPPORT.

- NOTCHING ON ONE GROOVE CAN BE DONE IS ABOUT 15 – 20 MINUTES.

- NAME MARKING ON ONE GROOVE CAN BE DONE IS ABOUT 10 MINUTES.

- 3-PHASE POWER SUPPLY & FOUNDATION AS PER MACHINE REQUIREMENT.

TWIN CHANNEL

OFFERS SOLUTION TO BAR HANDLING AT COOLING BED AT HIGH SPEEDS. TWIN CHANNELS ARE AVAILABLE FOR BAR SIZES UP TO 40MM IN INDIA AND STOCK SPEEDS AS HIGH AS 30METERS PER SECOND. THIS CARRIES THE BAR IN A CLOSED CHANNEL UNTIL THE MATERIAL COMES TO A STANDSTILL POSITION AND DISCHARGES IT TO THE BED BELOW AUTOMATICALLY.